Description

Ampetronic

ILD15 Lift / Elevator Induction Loop Driver

The ILD15 audio induction loop driver is a rugged amplifier primarily for OEM lift/elevator applications or other rugged industrial environments. Correctly installed it will provide full area coverage in most lifts to IEC60118-4.

The amplifier is constructed of a very robust steel housing, with vibration isolating connections and mountings to protect electronic connections, and is further protected by a 5 year warranty from Ampetronic. The amplifier has 2 independently controlled transformer isolated inputs. The audio system is designed for excellent intelligibility and includes metal loss frequency compensation to correct for the metal structure of the lift car. Battery backup is available as an integral option if required.

The magnetic field strength and distribution in a lift car will be highly dependent on installation method and the construction of the lift car. It is strongly recommended that you contact Ampetronic for free technical support and advice on the best methodology and design for your specific application.

N.B. The ILD15 solution may require a detailed application review by Ashton Audio and Ampetronic to ensure optimum operation in your application.

Robust industrial housing and vibration protection

5 year warranty

2 transformer isolated inputs (low impedance speaker line and 100V line options)

Metal loss correction

Battery backup option

Free support and installation advice

Full area coverage to IEC60118-4

Options

The ILD15 can be supplied with or without an integral battery back up system.

230V Power Option

Nominal supply voltage | 230 V 45-65 Hz |

Fuse | T 100 mA L |

Supply current (max) | 83 mA |

Supply current (quiescent) | 70 mA |

115V Option

Nominal supply voltage | 115 V 45-65 Hz |

Fuse | T 200 mA L |

Supply current (max) | 166 mA |

Supply current (quiescent) | 140 mA |

Battery Backup Option

The ILD15 can be ordered with battery backup (ILD15BB) or without (ILD15NB)

Battery capacity | 2 Ah 12 V |

Battery life | 12 hours standby plus 30 minutes full power speech operation |

Power indicator | LED inside unit indicates power status |

Charging | Custom charging circuit to optimise battery life |

Accessories

Loop Bars | 2 or 4 bar loop assemblies built to fit the lift and can be finished in the same colour as lift Interior. |

Standards compliance

The ILD15NB and ILD15BB are CE marked to all relevant safety and EMC standards.

The ILD15NB and ILD15BB will meet the requirements of IEC60118-4 and the relevant recommendations of BS7594 if specified and installed according to Ampetronic’s instructions.

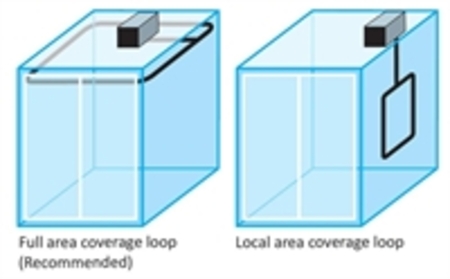

The ILD15 is designed to provide full area coverage of the lift car by driving a single turn loop around the perimeter of the lift car positioned at ceiling height. The loop must be placed inside the lift car behind non-metallic trim. The loop must not be behind metal panels or inside a metal enclosure in the roof space as this normally causes unacceptable reduction and distortion of the magnetic field.

There are two standard options for the loop itself:

LOOP BARS

The most robust solution is to attach custom built stainless steel loop bars to the ceiling inside the lift. Loop bars can be custom designed and supplied by Ampetronic to fit your specific requirements. Loop bars provide a robust and aesthetically pleasing solution with excellent performance.

LOOP CABLE

In some lifts it is possible to fit a single coil of 2.5 mm2 loop cable inside the lift behind non-metallic trim, or in rare cases inside the roof space if non-metallic.

Localised area coverage installationWhere an area coverage loop can not be installed, the ILD15 can be used to drive a smaller loop placed on or inside non-metallic wall panels or trim (for this type of application it is also possible to use other lower cost Ampetronic amplifiers if the high level of robustness and battery backup of the ILD15 is not required).

This style of installation restricts the useful magnetic field to an area no more than 1m from the loop coil, making such a small loop ineffective for large lifts and for use with a Public Address system or for safety communications such as a Voice Evacuation System.

Installation behind a metal panel or metal trim will rarely produce an effective magnetic field with any amplification method. Please contact Ampetronic for detailed guidance on the best installation method for your lift car or industrial environment.

ILD15 Specifications

Two versions are available:

Standard version: 1 x low Z, 1 x 100 V line input

Low level version: 2 x low Z input

Low Z speaker input | Input impedance: 5kΩ differential |

100V line PA Input | Input impedance: 136 kΩ |

OUTPUTS

Drive voltage | 1.5 V peak at max drive current |

Drive current | • >9 A peak with 1 kHz sine |

Loop connector | Vibration proof terminal blocks |

AUDIO SYSTEM

Freq. response | 80 Hz to 5 kHz ± 1.5 dB relative to 1 kHz at low level, measured as loop current with no metal loss correction |

Automatic Gain Control | AGC optimised for speech |

Metal Loss Correction | 0 dB to 3 dB / octave boost |

PHYSICAL

Cooling | Convection cooled |

Dimensions | Width 190 mm, length 255 mm, height 90 mm |

Weight | ILD15NB: 3 kg |

Environment | IP43: 0 to 90% relative humidity, -30 to 75 °C |

Ashton Audio in conjunction with Ampetronic can design your induction loop system for you. Simple induction loop designs are free, complex array systems will be charged for at a nominal rate. You can request a design through our 'Contact Us' Enquiry Form.